ElectroLab offers sulfuric acid Type II aluminum anodizing in Class 1 clear and Class 2 dyed accredited by NADCAP. The primary specification utilized is MIL-PRF-8625F(2) with capabilities to process in accordance with AMS, ASTM, and a variety of aerospace/military customer and commercial specifications. Our capabilities allow us to provide Type II anodizing on all aluminum alloys.

What is Anodizing?

Standard anodizing capabilities are augmented with the ability to provide electropolishing of the aluminum prior to anodizing, to produce bright metal finishing. We also offer a heavy etch that supplies a satin finish to the anodized parts on items that do not have critical dimensions or when critical dimensions can be masked. We provide vibratory enhancement of the finished parts. Our masking department has capabilities to mask certain areas of the part to prevent the anodize from covering to places. Our engineering department looks forward to planning multiple coverage processes, as we have years of expertise to offer as to process flow and masking design.

Type II Anodic Coating

Type II anodic coating is an essential and highly effective metal coating process utilized mainly in the manufacturing of aluminum-based products. It involves the process of creating a thick, durable, and non-porous layer of oxide on a metal surface through a methodical immersion process in an acidic electrolyte solution. This coating process results in a significantly more robust and hard-wearing layer of oxide in comparison to Type I anodic coating. Additionally, it offers improved electrical insulation properties and is widely preferred for its excellent abrasion and corrosion resistance capabilities. The Type II anodic coating finds its most common applications in architectural components, the automotive industry, and aerospace parts production. Although less transparent than its Type I counterpart, Type II anodic coating encompasses a wide range of colors that one can achieve using different dyes, making it aesthetically versatile.

We offer multiple sealing systems to the Type II anodic coating. Standard process for clear is a DI water seal. We also offer dichromate, nickel acetate, and duplex sealing, which is a combination of dichromate and nickel acetate seal or nickel acetate and boiling water.

Dichromate seal offers excellent improvement to the anti-corrosion capabilities of the anodize while nickel acetate improves the lightfastness of dyed Class 2, giving superior resistance to fading of the colors under exposure to ultraviolet light.

Type II Anodize

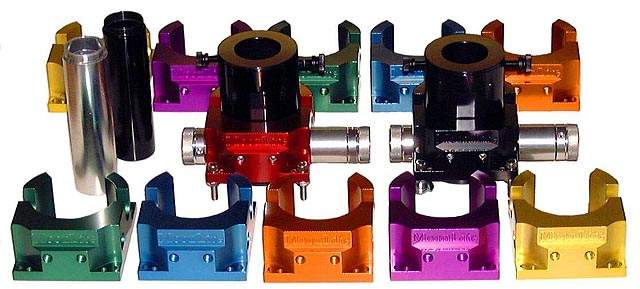

Type II anodize offer a superior ability to accept coloring through the application of organic dyes. We offer a wide spectrum of colors in both standard and bright finishes, including:

| • Black • Red | • Blue • Gold | • Green • Violet | • Neon (Pink) • Orange | • Teal • Turquoise |

Other colors are available for a nominal setup fee. Our engineering department can assist in matching a specific Federal standard or customer colors.

ElectroLab looks forward to the opportunity to provide your company’s anodizing needs. From the architectural consumer product to the automotive or highly specialized critical aerospace parts, we have the expertise, facilities, and complete capabilities to meet your requirements.