Stainless Steel Passivation: Enhancing Corrosion Resistance

Stainless steel is renowned for its durability, resistance to corrosion, and aesthetic appeal, making it a popular choice in various industries, from construction to medical

Welcome to ElectroLab II, Inc., where we specialize in delivering top-notch metal finishing processes that are Nadcap certified. Our commitment to excellence extends across various industries, encompassing commercial, military and defense, aerospace, medical, and automotive sectors. Additionally, we possess the expertise to cater to small orders, one-off projects, and custom finish requirements.

At ElectroLab II, Inc., we take immense pride in our ability to provide high-quality metal finishing solutions that meet the stringent standards set by Nadcap certification. Our dedication to precision and attention to detail ensure that our services consistently exceed expectations.

With extensive experience serving diverse industries, we understand the unique demands and specifications of each sector. Whether you require metal finishing for commercial applications, military and defense purposes, aerospace components, medical equipment, or automotive parts, we have the expertise to meet your needs.

Furthermore, our capabilities extend beyond large-scale projects. We are equipped to handle small orders, one-off requests, and custom finish requirements. No matter the size or complexity of your project, our team of skilled professionals is committed to delivering exceptional results.

Partnering with ElectroLab II, Inc. means gaining access to a trusted and reliable metal finishing provider. Our commitment to quality, precision, and customer satisfaction sets us apart from the competition. We strive to build long-lasting relationships with our clients, ensuring that their specific requirements are met with utmost professionalism and efficiency.

Experience the ElectroLab II, Inc. difference and let us transform your metal finishing needs into a seamless and exceptional process. Contact us today to discuss your project requirements and discover how we can assist you in achieving your goals.

When it comes to metal finishing and anodizing, finding a trustworthy company is crucial. You need a company with a proven track record of delivering premium finishing and electroplating services to industries like military, aerospace, automotive, and watercraft. Look no further than ElectroLab.

Situated in Oldsmar, Florida, ElectroLab takes pride in providing top-notch metal finishing services that cater to the unique requirements of each customer. We understand the fast-paced nature of today’s business climate, where time is of the essence. That’s why we offer a rapid response time without compromising on quality, all at competitive prices.

At ElectroLab, customer satisfaction is our utmost priority. That’s why we offer free pickup and delivery in the Tampa Bay Area, including Tampa, Clearwater, St. Petersburg, Lakeland, Sarasota, and Bradenton. We strive to make the metal finishing process as effortless and stress-free as possible for our valued customers.

Whether you require anodizing, electroplating, or any other metal finishing service, you can trust ElectroLab to deliver exceptional results. With our extensive experience and stellar reputation, you can rest assured that your project is in capable hands.

We provide large volume and small lot premium quality parts in a wide spectrum of finishes, with unprecedented turnaround and accurate job status tracking. We offer transportation through common freight lines and UPS®, FedEx®, and DHL®.

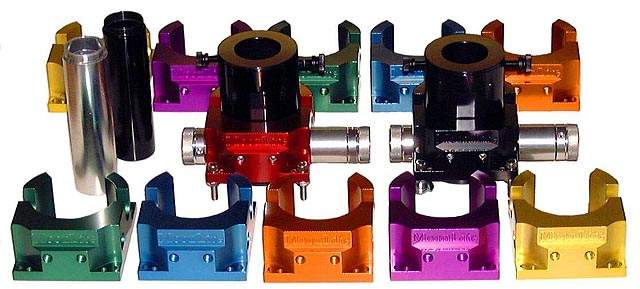

Anodizing is an electrochemical process that converts the metal surface into a decorative, durable, corrosion-resistant, anodic oxide finish.

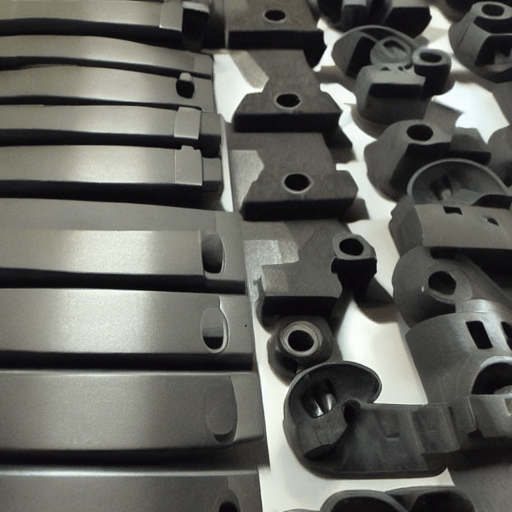

We provide multiple finishes including zinc, cadmium, and electroless nickel.

Chromate conversion coatings on an aluminium substrate are known by the following terms: chemical film, yellow iridite, and the brand names Iridite and Alodine

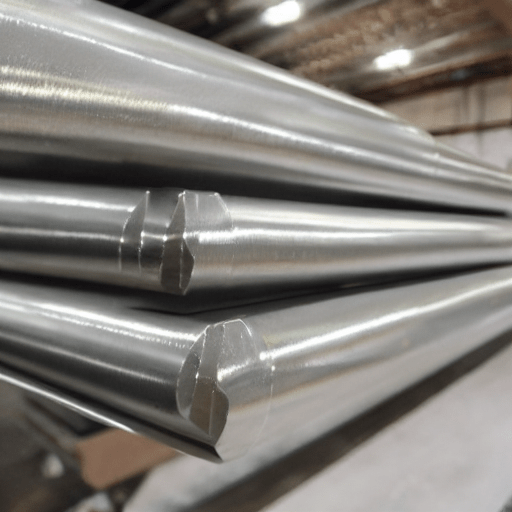

Passivation removes small spots on the surface that may begin to rust because grain boundaries or embedded bits of foreign matter left behind by machining or grinding allow water molecules to oxidize some of the iron in those spots.

Electropolishing removes iron from the surface and enhances the chromium/nickel content for the most superior form of passivation for stainless steel.

Black oxide or blackening is a conversion coating for ferrous materials, stainless steel, copper and copper based alloys, zinc, powdered metals, and silver solder. It is used to add mild corrosion resistance, for appearance and to minimize light reflection.

Electrolab has been named as one of the top 50 shops in the US.

Capabilies to meet your custom masking requirements with our in-house plotter.

Stainless steel is renowned for its durability, resistance to corrosion, and aesthetic appeal, making it a popular choice in various industries, from construction to medical

Cadmium electroplating is a widely used surface finishing technique that involves depositing a layer of cadmium onto the surface of a substrate material through an

Zinc electroplating is a widely used process in the manufacturing industry that involves the deposition of a thin layer of zinc onto various metal surfaces.

Anodizing is a widely used surface treatment technique that enhances the durability, corrosion resistance, and aesthetic appeal of metals. The process creates a protective oxide

BY TIM PENNINGTON, EDITOR-IN-CHIEF (FinishingAndCoating.com) Lonnie Harder doesn’t talk in grandiose terms about all that he wants to add or change about his Florida metal

This article was written by Marko Duffy, President of Marathon Manufacturing Services. It describes what is required and what should be taken into consideration when